Disrupting Dozers

The crawler dozer has been an essential element of equipment in the earthmoving industry for nearly a century. The dozer is a utilitarian tank of a machine, able to shove around dirt or push-load a scraper.

While the classic dozer has effectiveness in power, there are several key noticeable inefficiencies of crawler dozers on the jobsite, including operating speed and being a large capital expenditure with high maintenance costs.Construction and mining jobsites are fast-paced environments, which are focused on cycle time productivity. The top end speed of a crawler dozer maxes out at 8 mph. Due to this slow operating speed, the dozer can tend to be a bottleneck in jobsite productivity.The purchase of a crawler dozer is a large upfront capital expenditure. With many intricate parts and the need to buy additional options such as ripper shanks, that price can add up – and the costs do not stop there. Repair expenses on undercarriage components can quickly add up to be an expensive ongoing cash outflow for the contractor.Those shortcomings leave the door open for innovation where it comes to handling scrapers in the earthmoving and site prep sector. Could a machine with triple the top end speed of a standard crawler dozer be better able to keep up with push loading scrapers, as well as maintaining groundwork as a piece of support equipment?

K-Tec takes a new approach to scraper power

Two-headed tractor and attachments drive dozer replacement for scraper success

Instead of purchasing an expensive dedicated machine, why not purchase attachments that can effectively hook up to a power-unit that the contractor already may have in their fleet? The contractor could then easily remove the attachments from the tractor and use the power unit for other purposes. How about a machine that runs on wheels instead of steel tracks to minimize maintenance expenses?

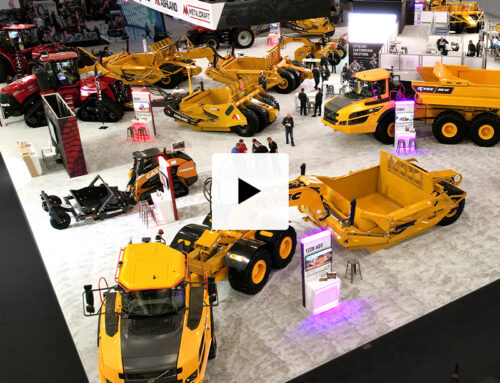

K-Tec Earthmovers is taking a shot at filling that space with the introduction of the Earthmoving Support Tractor (EST).

By using a 500+ horsepower tractor as the basic power unit, K-Tec is creating an efficient support equipment solution for contractors who already have this machine in their fleet. It is doing so by introducing two effective attachments: the K-Tec Ox Block, and the K-Tec Tricerabox.

The Tricerabox

On the front of the EST, the Ox Block is a pusher block purposefully designed for push-loading scrapers, providing increased capacity in an expedited cut zone time to improve productivity. The Ox Block is mounted by replacing the tractor’s front suitcase weights, offering balanced weight to the front of the unit. The Ox Block has automatic cushion-push technology, featuring hydraulic cylinders to reduce strain on operators and equipment. The Ox Block also comes standard with high-mounted LED lights, so that the machine can work on night shifts for critical around-the-clock operations. The Ox Block is narrower and positioned higher than a traditional dozer blade, which helps to minimize the chance of contact and damage with the rear scraper tires. Furthermore, the tractor has higher speed to return to the cut in time to push the next scraper, compared to a crawler dozer.

The Tricerabox is a 14-foot-wide box blade that is mounted to the 3-point hitch on the rear of the EST, engineered to engage the ground and manipulate soil. The three functions of the Tricerabox include the levelling blade pulling material forward, ripper teeth sinking down into the soil, and blade backward for pushing material similar to a dozer.

The Tricerabox has seven ground ripper shanks that are hydraulically operated to lower for engaging the ground for ripping up hard soil or aerating wet jobsites. The Tricerabox back blade allows the operator to complete backfilling of soil work, fully smoothing out the cut and fill zones. The three-point hitch may also be modified to have a scraper hitch hook-up, making it the ultimate piece of support equipment, where the tractor can fill in as a bulk dirt hauler for another power unit that may be down for maintenance.

The Earthmoving Support Tractor is an excellent way to give tractors a second life as an integral piece of earthmoving support equipment. The operator will enjoy using the tractor as it has a comfortable environment inside a full-suspension cab that is sound suppressed and isolated from the chassis. The large window visibility and swivel tractor seat make it ergonomically enhanced for all functions of the K-Tec EST.

Tractors also have a buddy seat in the back, which is ideal for training new operators on efficient use of the EST. Another advantage of the tractor is that the operator has storage area space and a tool box for being able to take care of minor mechanical repairs on site. The fully hydrostatic tractor also offers a tight turning radius for machine maneuverability, making it an ideal disruptive force compared to the traditional crawler dozer.