Earthmoving for Everyone

Humanity has an innate desire to create, build, change, and improve our environment to advance our existence. The projects that we bring into reality may vary, but one thing is almost universally constant; earth must be moved. To this end, we find earthmovers everywhere with a variety of materials to be moved from one location to another. The optimal equipment selected to move this material is dependent on the application, and the machines that are already owned by the earthmover. Contractors of all sizes can use their existing fleet of prime mover power-units to easily move bulk material by attaching a scraper. Whether you move millions of cubic yards of material as a heavy construction equipment manager or a solo landscaping contractor sculpting residential properties, there are scrapers available to make your task of moving material more effective and improve the versatility of your fleet. Explore the sections below for the broad variety of scraper uses in industrial mining, construction earthmoving, land leveling contracting, agricultural farming, hobby farming, or landscaping contracting.

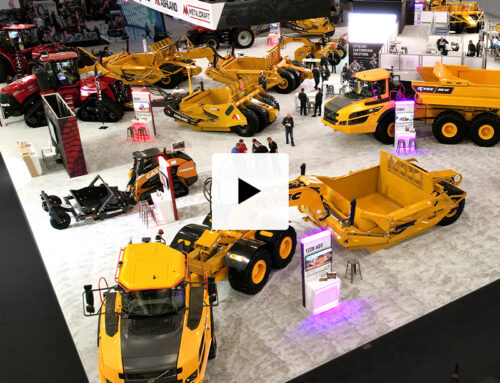

Industrial Mining Operator: Scraper Selection

Industrial mining operations have long-term project horizons with the goal of extracting valuable minerals as efficiently as possible. Capital intensive mining equipment fleets are placed in the most demanding environments. Mines require long-lasting machines that will perform with maximum uptime, as operation shifts may run around the clock.

Mining tasks including stripping overburden, mine reclamation, haul road smoothing, and paydirt transportation are ideal scraper projects.

For mining operations with long and rocky haul roads, where maneuverability is desired, owning a fleet of 50-60 Ton Articulated Dump Trucks (ADT’s) as scraper haulers is a novel improvement over traditionally loading Rigid-Frame Dump Trucks (RDT’s) with excavators. Currently in the market, only Volvo and Bell offer ADT’s in this largest size category.

Forward-looking mining operators have experienced advantages over their competition by utilizing an existing fleet of ADT’s and converting them into efficient, self-loading scraper haulers. K-Tec’s ADT gooseneck scraper design, along with a model-specific truck hitch, alters an ADT unit to haul more material. By converting an ADT into a scraper hauler, advantages are gained over smaller earthmoving equipment, as fewer trips to the dumpsite equates to money savings by trimming out wasted driving labour and fuel costs. The ADT transformation process takes less than 10 hours to remove the dump bed and install the hitching system to connect the scraper for becoming a single operator mass excavation machine. It is a fully reversible transformation procedure, so if a dump body is needed for hauling boulders, the truck can easily be converted back.

50 Ton articulated trucks have features to make them easy to operate and maintain. The truck’s multi-speed transmission provides an improvement in the ratio steps between gears for increased performance. With the price point and size of 50 Ton trucks compared to expensive RDT’s, contractors gain production and value for their capital expenditure investment.

Using a single power unit and one operator, the K-Tec 1237ADT Train doubles up efficiency by pulling two 1237ADT scrapers. On job sites with longer cut-zone and haul road areas, a massive advantage is gained to provide a tandem heaped capacity of 74 Cubic Yards (56.6 m3). The 1237ADT Train provides impressive production performance at the end of the day. This configuration has an added advantage since it can also split into single scraper units on mining sites as project requirements change.

More information on the K-Tec 1237 ADT Train scraper specifications can be found here: https://ktec.com/products/train/1237adt-train/

60 Ton ADT’s are currently the largest articulated trucks on the market. With long service intervals, this machine delivers performance. The 60 Ton ADT’s may have an active hydraulic front suspension to permit high hauling speeds and stability to travel in tough conditions. Work in all seasons, terrains, and applications using machine configurations and tires, optimized for the 60-tonne machine. The 60 Ton ADT’s provide great versatility for accessing the entire jobsite with steeper gradients.

When the job requires larger capacity with long haul roads, the K-Tec 1243ADT excels even in the toughest conditions. The 1243ADT scraper is proficient in self-loading behind the 60 Ton ADT’s however, a standard roller push block on the back of the scraper is included for smooth push loading if even faster cycle times are desired of the 43 Cubic Yard (32.9 m3) heaped capacity scraper.

More information on the K-Tec 1243 ADT Train scraper specifications can be found here: https://ktec.com/products/adt/1243adt/

Earthmoving Construction Contractor: ADT Scraper Selection

For contractors that consistently work in hard ground conditions with longer haul road distances, owning a fleet of Articulated Dump Trucks (ADT’s) to gain fleet versatility by converting into scraper haulers is a smart, long-term solution.

For the smaller 25-30 Ton range class of Articulated Dump Trucks, a tighter radius allows for better handling and control. This improved maneuverability is ideal for job sites that require navigating tight corners, allowing the operator to drive with more confidence and precision. Contractors are able to convert their existing fleet of Volvo, Caterpillar, Bell, Rokbak, and Komatsu trucks are several brand examples of ADT’s that commonly pull K-Tec scrapers.

The 25-30 Ton class of Articulated Dump Truck may feature advanced automatic traction control to detect possible slippage, to allow the truck to perform consistently better while loading the scraper. The 6-wheel chassis provides plenty of traction and power to the ground to be converted from a dump truck into a scraper hauler.

The K-Tec 1228ADT scraper is a mighty machine with nimble maneuverability. K-Tec’s lowest cost ADT scraper to set up provides high production on smaller job sites with tough conditions. The solid-welded, rigid-frame 1228ADT, carries a heaped capacity of 28 Cubic Yards (21.4 m3). The 1228ADT is an attractive choice for contractors with older or idle 25 to 30 Ton ADTs in their fleet to transform into efficient and versatile scraper haulers.

More information on the K-Tec 1228 ADT scraper specifications can be found here: https://ktec.com/products/adt/1228adt/

The 40-45 Ton range class of Articulated Dump Trucks offers additional horsepower and body strength to provide pull a larger payload for jobsite productivity. There are a broad variety of manufacturers in the 40-45 Ton ADT space including Caterpillar, Komatsu, Volvo, Bell, Rokbak, Doosan, Hyundai, and Deere.

40+Ton trucks provide rugged off-road performance and may have features including 100% differential locks, all-terrain bogie, and hydro-mechanical steering. The truck’s downhill speed control function automatically maintains a constant speed when operating on downward gradients for an efficient and comfortable shift.

The K-Tec 1237ADT is a ruggedly versatile earthmover, making it K-Tec’s most popular ADT scraper favored for equipment fleets. The modular 1237ADT scraper is a fast, strong, multi-purpose machine; carrying a heaped capacity of 37 Cubic Yards (28.2 m3), is a powerful worker in any soil condition or job site application.

More information on the K-Tec 1237 ADT scraper specifications can be found here: https://ktec.com/products/adt/1237adt/

Earthmoving Construction Contractor: Tractor-Drawn Scraper Selection

Earthmoving excavation contractors have a wide variety of responsibilities including site preparation, grading, and soil management. They own a fleet of heavy iron equipment and have a staff of trained operators to complete the work effectively.

For contractors the consistently work in soft soil conditions with relatively short haul road distances, owning a fleet of high horsepower 4WD tractor drawn scrapers is the ideal, affordable solution.

Case IH, John Deere, AGCO, Versatile, G.A.M.E, and New Holland, manufacture high-horsepower 4WD tractors for scraper applications.

Scraper-Special tractors deliver high-performance, requiring an increased high-flow hydraulic system. Falling-object protective structure (FOPS) is an important safety consideration for construction work environments, as scrapers can be top-loaded with an excavator in bulk earthworks applications as well.

The K-Tec 1233 scraper is a ruggedly versatile earthmover. Its modular, bolt-together design, allows for affordable international container shipping, and minimal maintenance. This strong, multi-purpose machine, carrying a heaped capacity of 33 Cubic Yards (25.2 m3) is a powerful worker in any soil condition or job site application. The 1233 scraper can also be converted into a Lead Train or Rear Convertible to have your equipment fleet grow with your company.

More information on the K-Tec 1233 scraper specifications can be found here: https://ktec.com/products/dm/1233dm/

Construction Owner-Operator Contractor: Scraper Selection

A construction owner-operator is a professional earthmover who owns their own equipment and hires out their earthmoving activities as a service to others who need material moved. Earthmoving owner-operators typically use a 4WD high-horsepower tractor and pull a scraper for an efficient one-person excavation operation. Owner-Operators take pride in their equipment, take special care of maintenance, and focus on performance for profitability.

Various 4 Wheel-Drive Tractors for land leveling contractors are manufactured by AGCO, John Deere, New Holland, Case IH, and Versatile.

These tractors are proven workhorses on construction sites, moving earth at the lowest possible cost per yard. Four-track tractors have individually driven tracks, which maintain constant contact with the ground for a smooth ride, superior flotation, and optimal ground pressure. Enhanced traction is always delivered, even in wet or slippery spots. These powerful tractors pair perfectly with pull-pan scrapers.

The Ashland 2411E scraper has design features that allow loading and unloading with ease without double ejecting. The front section is attached low to the bowl just over the cutting edge. This lower pull point provides a smoother cut at a faster speed. The vertical position of the lift cylinders enables faster blade response, allowing for the tractor to pull the desired powerband for making large, quick loads of up to 24 cubic yards (18.3 m3). The long hitch transfers 77.5% of the load weight onto the rear tires while reducing the weight placed onto the tractor. The narrow 11’ width of cut is just wide enough to clean up the tractor’s four-track tread path for a smooth cut zone operation.

More information on the Ashland 2411E scraper specifications can be found here: https://ashlandind.com/products/2411e/

Land Leveling Contractor: Scraper Selection

In areas such as the Mississippi River Delta, Land Leveling Contractors are companies that are dedicated to shaping the land for optimal drainage and irrigation. Water management is critical in these areas to get the most out of the land with their 4WD tractors. Land Leveling contractors frequently use GPS systems to streamline the surveying, designing, and leveling steps required for land leveling projects to provide improvements in yields, water usage, and farm productivity.

4 Wheel-Drive Tractors for land leveling contractors are manufactured by Versatile, New Holland, AGCO, G.A.M.E, Case IH, and John Deere. These special application scraper tractors are as big on hydraulic power as they are on raw horsepower, meeting today’s demanding standards for scraper operations. Large side mirrors and a wide-angle inside mirror help keep an eye on towed scrapers without having to twist around.

The Metalcraft 2016E scraper is the optimal choice for a land leveling contractor. The broad 16’ width of cut allows owner-operators to efficiently skim off layers of soil to even out large fields for optimal drainage and finishing grade. The unique cross-tilt capabilities of this scraper allow the operator to sculpt the soil by adjusting the angle of the scraper blade. The 2016E can collect a heaped capacity of 20 cubic yards (15.3 m3) of material in the bowl and transport it to fill in low-lying areas on the field. Further precision efficiency can be gained by incorporating dual GPS, and the optional shock-absorbing skis to obtain faster leveling speeds and a smooth finish.

More information on the Metalcraft 2016E scraper specifications can be found here:

https://metalcraftscrapers.com/equipment/#tilt

Agricultural Farmer: Scraper Selection

Bigger farming operations have a larger number of acres to farm annually. Subsequently, they may have the need for hired workers as well as larger tractors available in their machinery sheds to get all the time-sensitive work completed efficiently. High-horsepower MFWD tractors or 4 Wheel-Drive Tractors are most common in large farming operations and can be extremely useful for scraper applications of drainage optimization with the goal of increasing yields for the following harvest.

Manufacturers of High-horsepower MFWD tractors or 4 Wheel-Drive Tractors include Fendt, CLAAS, Case IH, John Deere, AGCO, Versatile, and New Holland.

For ditching applications when traction advantages are essential to your operation, tracked tractors are ideal for superior traction and flotation. A Continuously Variable Transmission (CVT/CVX) is ideal for pulling scrapers as it delivers the exact speed for simple loading operations.

A direct mount scraper offers superior visibility to the cutting edge, compared to dolly-wheel scrapers. Direct mount scrapers with a 25% – 75% weight transfer ratio, put just the right amount of weight on the back of the tractor to provide optimum flotation and traction for efficient earthmoving.

Farmers can experience improved performance with more traction and faster loading speeds with a direct mount scraper. The narrow 10’ width of cut Ashland 1410E is an optimal ditching scraper for sculpting field site drainage. The Ashland 1410E is a rear lift ejector scraper, allowing the floor of the scraper to remain nearly flat while loading, making drainage and ditch clearing a simple task. The side router blades extend beyond the blades to funnel material into the bowl while loading the scraper to a heaped capacity of 14 cubic yards (10.7 m3). The scraper’s forward-placed router blades are beneficial when loading loose material while leveling the ground for irrigation.

More information on the Ashland 1410E scraper specifications can be found here:

https://ashlandind.com/products/1410e/

In smaller farming operations, farmers grow grains such as corn, wheat, and other crops, or may run a livestock operation in a hardworking profession to feed the world. Many of these farmers own their land and work for themselves. After harvest is complete, smaller-scale farmers look for ways to use their small to mid-sized mechanical front-wheel drive (MFWD) tractors effectively on their fields to prepare for next year’s crop.

Efficient, reliable, multi-purpose MFWD tractors have enough power for livestock applications, row-crop fieldwork, or scraper work. These tractors provide power and comfort and are perfect for long days in the field moving material.

There are a variety of brands that offer small to mid-sized mechanical front-wheel drive tractors including John Deere, New Holland, Versatile, and Case IH.

These tractors are designed to provide the hydraulic capacity and horsepower to pull scrapers. Ensure that the tractor has the hitch capacity, hydraulic component features, and hydraulic flow available to handle scraper application requirements. A dolly wheel scraper can be pulled with any standard ag hitch and carries its own loaded weight, making it a quick and simple earthmoving solution on the farm. These earthmovers are a great solution for maintaining and improving farmland.

The Ashland 950XL2 scraper has a history of proven performance that can be relied on for all ag applications. Designed to be pulled by a small to mid-sized mechanical front-wheel drive (MFWD) tractor, the 950XL2 is Ashland’s smallest ejector scraper for farms and fields. Its narrow width allows for maneuverability through feedlot gates and other tight areas where dirt needs to be moved. The weight of the 9.5 cubic yard (7.3 m3) capacity of heaped material is shared between the scraper bowl and dolly assembly, to minimize the loading effect on the tractor.

More information on the Ashland 950XL2 scraper specifications can be found here:

https://ashlandind.com/products/950xl2/

Hobby Farmer: Scraper Selection

Hobby farmers typically own less than 50 acres of land and strive to be self-sufficient by raising a farm to reap the fruits of their labor for their own enjoyment. A utility tractor is a primary machine that the hobby farmer uses to get various jobs done.

Various manufacturers offer utility tractors that are useful for hobby farms including Kubota, Mahindra, Massey Ferguson, John Deere, Case IH, & Fendt.

In the case that the hobby farmer’s acreage frequently needs dirt or compost moved around to manage their operation, a pull scraper with a larger capacity is desired instead of using the standard front bucket on a tractor. A front-wheel assist utility tractor with a heavy-duty drawbar is an ideal match for a scraper attachment.

Ashland’s 50CS is a compact scraper for the hobby farmer or rancher. The 50CS is a ruggedly simple machine that pairs perfectly with 70+ horsepower utility tractors to move a 5 cubic yard (3.8 m3) heap of material. This durable and affordable scraper can move materials for a variety of project needs; from pond and waterway construction to cleaning poultry barns. With its modular design, even maintenance and repairs are easy on the Ashland 50CS scraper.

More information on the Ashland 50CS scraper specifications can be found here: https://ashlandind.com/products/50cs/

Landscaping Contractor: Scraper Selection

Landscaping contractors sculpt the earth by modifying slopes and grades, shifting mounds of soil from one side of a lot to another. This soil artistry results in a beautifully finished project. A Landscaper’s equipment fleet typically consists of smaller, nimble machinery to quickly maneuver throughout the workday. A Compact Track Loader (CTL) is a nimble rigid-frame machine with lift arms that can attach to a wide variety of labor-saving tools or attachments, including scrapers.

There is a broad spectrum of CTL manufacturers including Bobcat, Case, CAT, Deere, Gehl, JCB, ASV, Kubota, LiuGong, Manitou, New Holland, Takeuchi, and Wacker Neuson.

Any existing brand of 74+hp CTL owned by the landscaping contractor can be paired with Ashland’s 3250SS Scraper to load and transport bulk material efficiently. The scraper’s 81.5″ width of cut perfectly fits these larger track loaders. The 3250SS can cut, carry, and dump up to 3.25 cubic yards (2.5 m3). With the 3250SS, large landscape projects can be quickly finished, and on construction sites, the scraper can assist in cleaning up around the jobsite. The integrated leveling blade handles final grading in a single pass.

Contractor MKC located in Sacramento, California owns a fleet of 6 skid steers with front-mounted Ashland scrapers. This earthmoving method follows the “ant colony strategy”, where many small machines can move a great amount of material together.

More information on the Ashland 3250SS scraper specifications can be found here: https://ashlandind.com/products/3250ss/

A Scraper for Every Power-Unit

This broad spectrum of pull-pan scrapers enables contractors of all sizes to use their existing fleet of prime mover power-units to easily move bulk material. Unlock the potential of your existing equipment or idle fleet prime movers by turning them into efficient scraper haulers. Whether you own a fleet of numerous Articulated Dump Trucks, an agricultural tractor, or a single CTL skid steer, there are scrapers available to make your task of moving material more effective while optimizing your equipment fleet versatility.

Article Written by Shane Kroeker, Director of Strategic Initiatives, K.A. Group

K-Tec Media Contact

Shane Kroeker

Director of Strategic Initiatives

K-Tec Earthmovers Inc.

T: 1-204-746-6435

ShaneK@ktec.com