Laying the Foundation

Graders and scrapers play the key role in concrete road building. Building a concrete road starts with a solid foundation, and graders and scrapers are pivotal pieces of construction equipment in the process.

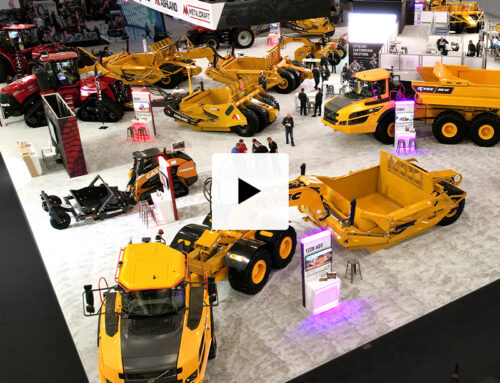

“Large road projects like interstate highway expansions and turnpike corridors are of vital infrastructure importance. Often these projects require millions of cubic yards of material to be moved, with timelines being expedited to under seven months of construction work from start to finish to mitigate traffic constraints and delays,” says Shane Kroeker, spokesperson for K-Tec Earthmovers.

If an operator is inconsistent in holding the correct grade, the finished gravel may be wavy and transfer up to the finished concrete, putting the road out of spec and possibly requiring grinding or removal.

The first of several layers of building a concrete road often involves cutting massive amounts of material out of high spots to relocate to low spots.

Required equipment may include scrapers, excavators, loaders, dozers, trucks, rollers, and graders.

Once this material has been moved, the bottom layer is put to grade with the motor grader.

In the cut area, scrapers load material and cut the grade down. As long as the scrapers don’t overcut or dig too deep, the cut portion is fairly straightforward. Scrapers dump the material in the fill area to bring the grade back up. Consistent lifts of material and compaction are critical in creating a resilient road base.

Drawn scrapers with multiple tires and high weight offer high compaction levels without the need for additional equipment.

As trucks dump the material used for each layer, the material on the ground needs to be processed to get the correct moisture content and placed at the correct location and elevation on the roadbed. The motor grader is very good at this process. As the operator rolls material across the moldboard, it helps mix the water into the material. The grader is then used to place the material across the roadbed at the correct depth.

Rollers are then used to compact the layer. The grader puts the layer to its finished grade, often using GPS for accuracy.

The process continues until the contractor reaches the finished gravel grade and lays concrete, which must be at a precise elevation to tie in with bridge decks and existing roads to ensure sufficient clearance under overpasses.

Achieving tight grade tolerances prevents excessive material use.

Managing optimum moisture content in the base course material during the finish grading process aids in meeting compaction specifications. When the base course meets compaction and finish grade requirements, it allows for an excellent surface to support the concrete road.

Motor graders help achieve a finished grade surface that delivers the ability to add the next lift while preventing material overruns.

K-Tec’s Pull-Pan Ejector Scrapers are designed to complete the three functions of earthmoving by picking up, transporting, and smoothly ejecting a load of material, says Kroeker.

Scrapers are designed to provide multiple configurations to achieve high levels of compaction in the fill area while reducing the need for excessive haul road maintenance.

Scrapers can maximize ground pressure in two-tire configuration or coverage area in four- or six-tire configuration in addition to tractors with single or dual wheels, two tracks or four tracks, for consistent compaction in the fill regardless of material types.

Scrapers are used to build pads or roadway surfaces by quickly moving multiple material types in different ground conditions.

Scrapers with a high tire ground pressure rating, are considered a benefit in fill locations as it compacts the pad or base as the lifts are being placed to provide a solid base and, in some cases, eliminating the need for additional compaction equipment.

The standard open bowl machines are optimal for bulk earthmoving.

They are designed to get load very quickly and place the material in the fill. As the project gets closer to grade—depending on the material type of the open bowl—the scraper will be able to leverage Grade Control and put the project on grade.

Grader specifications depend on job site variables such as size and work scope, which determines the machine’s size, weight, moldboard width, and type of ground engaging tools needed.

A K-Tec 1243 moves dirt on an airport project.

A K-Tec 1243 moves dirt on an airport project.

Scalable technology solutions drive increased productivity, efficiency, accuracy, and profitability.

Operator or fleet preferences determine the motor grader control system needed, joysticks or steering wheel and lever. Underfoot conditions, material type, and job site applications determine whether a rear tandem drive machine or an all-wheel-drive machine is needed.

All-wheel-drive is beneficial for slope work, ditch cutting, and working in sand or wet conditions.

It’s also beneficial for cutting finish grade as the system can engage the creep mode feature to disengage the rear tandems, with the front wheels pulling the machine along at 0 to 5 mph.

For many years, plus or minus a tenth of a foot was the industry standard, but now there can be just a few millimeters’ tolerance for a new road.

Many jobs also will have specs as tight as plus or minus 1% on moisture and each layer on the roadbed will have specs for compaction. If the moisture and compaction requirements are not met, the contractor is required to rip that section up and start over.

Another key aspect of obtaining good compaction is how the lifts of material are placed before compaction.

If the scraper is not equipped with a grade control system, this height is solely at the operator’s discretion, leaving a lot of room for inconsistencies.

K-Tec’s earthmoving scrapers are suited for large road-building projects, with high-capacity single scraper models ranging from 28 to 63 cubic yards in a heaped bowl, says Kroeker.

Some of K-Tec’s scrapers can work in train configuration to achieve a tandem heaped capacity of 74 cubic yards behind a single power-unit.

“To speed up cycle times, contractors may use an articulated dump truck to pull the K-Tec scraper to achieve faster haul road speeds of up to 35 mph,” says Kroeker.

A K-Tec 1263 ADT pull scraper

A K-Tec 1263 ADT pull scraper

The K-Tec Scraper has four large tires spread across the back of the machine designed to help roll over and compact the smoothly-ejected load of material.

The precision finish grade also is a key specification required for roadbuilding projects to ensure slopes and ditches meet standards, says Kroeker.

K-Tec scrapers come Trimble GPS-ready to ensure finish grading applications and bulk earthworks with the scraper are as close as possible to final specifications.

A K-Tec 1237 ADT working at a sand quarry

A K-Tec 1237 ADT working at a sand quarry

K-Tec’s ADT Scraper system enables trucks to be utilized for a new purpose with drivers transitioning to an effective scraper operator behind the same wheel, says Kroeker. It features six-wheel drive and K-Tec’s Scraper Automatic Cushion Ride System.

The operator’s eyes can face forward by using the truck’s backup camera that is angle-adjusted towards the cutting edge to view the material flow into the bowl, says Kroeker.

K-Tec’s ergonomic padded armrest and multi-function joystick control are attached to the truck’s operator seat. The cab’s operating system offers a selection of automatic ejector modes for specific soil types and an even spread of the material, optimal for training new operators, says Kroeker. The operating system displays automated load counting productivity and operator service maintenance reminders.