Saving Earthmoving Costs,

One Dollar at a Time

Dollar Tree, Inc., North America’s leading operator of discount variety stores, has construction underway for a new 1.2 million-square-feet distribution facility in Ohio’s Morrow County, Bennington Township. The company is investing more than $125 million into the project, that will provide service directly to Ohio’s 735 existing Dollar Tree and Family Dollar stores. Construction began in summer of 2018, and has an aggressive timeline with the facility being operational by summer 2019.

Clancy & Theys Construction Company headquartered out of Raleigh, NC is the general contractor on the Morrow County, Ohio Dollar Tree distribution center project to be fully constructed in June 2019. In order to meet the tight time frame, the earthworks responsibility of the project was put out to tender, where 3 Ohio-based contractors submitted interest in tackling the challenge, using their earthmoving expertise.

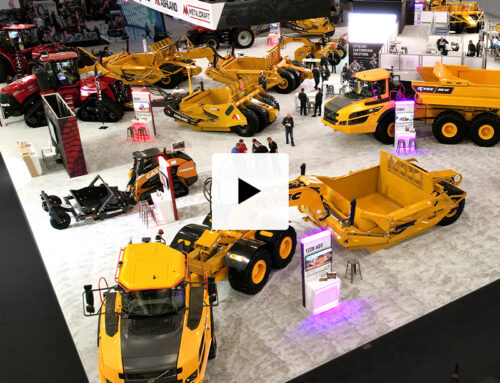

Trucco Construction Co. of Delaware, Ohio put in a bid on the project based on earthmoving production numbers by using 7 K-Tec scrapers, being pulled with Volvo Full-Suspension Articulated Dump Trucks (ADT’s), and over a dozen other pieces of various earthmoving support equipment. Rudd Equipment Company, being a dealership for both the Volvo ADT’s and K-Tec scrapers, provided a seamless product solution and support for Trucco to make a strong proposal for their project pitch. Rudd Columbus Branch VP, Martin McCutcheon considers, “What the customer looks at is the cost per yard that they are moving material, so when we look at the overall cost with the K-Tec scraper married up to the Volvo A45 artic truck, then your costs are so much lower. When you put everything together from the K-Tec quality product, to the Volvo quality product, it is hands down as far as cost per yard, the best product that is out there, with a quality dealership in Rudd standing behind it.” Due to this advantage in cost and production performance, Trucco managed to successfully outbid the other two other contractors who were planning on moving dirt with other earthmoving equipment combinations, and were awarded as the earthworks subcontractor for the project.

Trucco had 2 months to complete the earthworks on the Dollar Tree distribution center project, requiring over 500,000 cubic yards of clay & topsoil material to be moved. Regarding site production efficiency, Dave Overholt, Superintendent for Trucco Construction notes, “We are trying to move over 20,000 cubic yards a day. We self-load when stripping the topsoil, and we typically push load the K-Tec’s in the high-moisture, clay cut material.” Rain is always a concern in Ohio, and Trucco’s use of K-Tec equipment has been strategic and advantageous. The fleet is able to get into wetter underfoot conditions with the K-Tec scrapers, compared to their traditional twin-engine scrapers, as the K-Tec machines do not pump out the soft haul road.

A well-maintained 750-foot haul road is critical for the 5 to 6-minute cycle time productivity on this jobsite. The smooth ride of the Volvo Full-Suspension Articulated Dump Trucks, and the Automatic Cushion Ride system of the K-Tec Scraper makes for an enjoyable ride for operators to complete their jobs comfortably and productively. This combination, Overholt says, “Is basically the only way to go. They are very easy to adapt to the operators. The operator isn’t getting beat around, and can run at high speeds on the haul road, the ride is tremendous.”

Even with the tight project timeline, Trucco Construction has utilized their earthmoving assets to their advantage on the jobsite. Trucco experienced 39 weather days during the project, with 56 inches of rain (a seasonal record high for the area), yet the company still came in on time for the building pad earthwork and did not hold the project up for any other subcontractors. True to the original project estimations, the Volvo ADT and K-Tec Scraper Fleet performance was averaging right at the 20,000 cubic yards per day, and sometimes even exceeded expectations by moving upwards of 23,000 cubic yards in a day. Trucco has an additional 50,000 cubic yards of supplementary earthwork to move on the Dollar Tree property to wrap up in spring of 2019.

Overholt considers future scraper investments for Trucco’s fleet, “I can see us in the near future, buying a couple more. They’re just the way to go.” From being able to quote the job at a lower cost per cubic yard than their competitors, to handling wet conditions, as well as making a profit for their own organization, the production efficiency and savings of using the Volvo ADT and K-Tec Scraper earthmoving fleet seem to be making money grow on trees on this earthmoving project.

To watch Trucco in action on the Dollar Tree Project, please view the jobsite video at: https://youtu.be/rPSzfr3Y4T4

About Trucco Construction Company, Inc.,

Since its inception in 1990, Trucco Construction Company, Inc., has quickly become an industry leader in Central Ohio and the surrounding areas.

Founded with the time-honored principles of honesty, integrity, hard work and craftsmanship, Trucco was built on a solid foundation. Although rooted in tradition, Trucco still keep abreast of the best that the construction industry has to offer its customers. So, while methods have constantly adapted to embrace improving systems and emerging technologies, the fundamental character of Trucco’s foundation is unwavering.

This artful blend of old and new, of tradition and innovation, combined with a customer-centric approach to business has made Trucco one of the largest, fastest growing family-owned businesses in the area.

About Rudd Equipment Company,

Rudd Equipment Company provides complete equipment sales and service support to the mining, construction and associated industries. Rudd is the exclusive distributor in the Midwest for internationally recognized and preferred manufacturers and are among the oldest and largest distributors in the world for Volvo articulated haulers.

For 67 years, Rudd has been dedicated to servicing the customer, and pledges quality product support, demonstrated in employment of award winning, factory-trained technicians, professional and knowledgeable sales people, and a commitment to consistent parts and service availability.