When it comes to volumes of dirt moved, the sky is the limit for scrapers, notes Shane Kroeker, vice president of marketing for K-Tec Earthmovers. And, for moving earth on a job site, the scraper serves as a versatile piece of equipment, offering the ability to move a wide range of material and work in a variety of job-site conditions.

While pull scrapers are designed to move earth, there are different types of applications for doing so, such as at a landfill, in a mining operation or in road construction, they’re used in different types of applications, but—at the end of the day—their job is to move as much dirt as at least expensively and as fast as possible for the owner of the project.

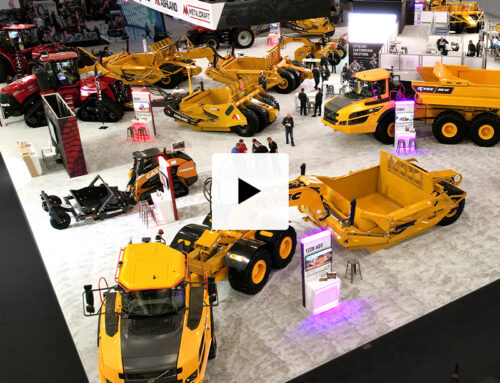

Scraper options abound on the marketplace.

K-Tec’s 1237ADT Train

The focus of scraper pan choices is between a four-wheel drive tractor and scraper system, versus the self-propelled scraper. When you look at the initial investment in a four-wheel drive, it’s about a third of the investment and half of the labor because you only need one operator. The system is designed to provide a savings of 50 cents per cubic yard of material moved.

Ejector scrapers are chosen for material that is heavy, wet, or sticky, and the need for hydraulic cylinders to push the material out.

K-Tec’s high-capacity scraper models range from 28- to 63-cubic yard capacity, with the ability to train scrapers in tandem to carry a heaped capacity of 74 cubic yards, says Kroeker.

K-Tec scrapers are versatile in that they can be push-loaded and top-loaded and have excelled in loading topsoil, clay, sand, coal, gravel, or gypsum rock for various job-site materials, says Kroeker.

“For further versatility, K-Tec’s popular bolt-together 1233 model allows for the contractor to easily swap hitch poles so that the scraper may be pulled by either a tractor or an articulated dump truck,” he adds. “This factor maximizes fleet versatility, reduces downtime, and provides for a higher resale value.”

The company’s tractor-towed pull scraper has been designed to reduce costs and increase efficiency over a self-propelled scraper or truck and excavator earth-moving equipment system. Given the options on the market, there are a number of factors that go into the process of selecting a scraper.

Kroeker cites six factors to consider when determining which earthmoving equipment combination is optimal for a job site—going with an ADT and scraper, or with a tractor or scraper:

- Site condition. A tractor and scraper combination is preferred for soft, spongy soil, while an ADT scraper is indicated for hard, rough soil, and steeper grades.

- Haul length. A tractor and scraper combination is ideal for short haul distances of a half mile and less for cut and fill applications. In longer haul distance beyond one-half mile, an ADT and scraper combination is ideal to achieve the 30 mph and higher transportation speeds to shorten cycle time.

- Material. Topsoil, clay, sand, and gravel may easily be moved with either combination, but shot rock and gypsum are recommended for ADT scraper combinations.

- Volume. ADT and scraper combinations are indicated for earthmoving projects with more than 250,000 cubic yards. Tractors and tandem scrapers are used for large earthmoving projects with a short haul road.

- Longevity. ADT and scraper combinations are ideal for projects with long durations and working hours.

- Cost. Tractor and scraper combinations have a 20 to 30% affordability advantage over ADT and scraper combinations.

“Should a project have millions of yards required to be moved or a requirement to move a mass amount of material in a short timeframe, increasing the scraper fleet size is the solution to meet these goals successfully,” says Kroeker.

There are instances where a contractor will need more than 10 new scrapers immediately onsite as soon as they are awarded a large project, he points out. The company’s website offers a cost analysis calculator tool to help determine how many scrapers are required for a contractor to reach and exceed annual goals of material to be moved.

If a contractor is involved with an earthmoving project and already owns an existing power unit, such as a tractor or articulated dump truck, “the decision to use a pull-pan construction scraper is simple to minimize capital expenditures for the operation,” says Kroeker.

Phares notes a correct analysis of those factors involved in selecting a scraper are critical in calculating job times in order to figure out a project’s overall cost.