K-Tec is first to build sustainable earthmoving equipment with fossil-free steel in collaboration with SSAB

K-Tec has entered an agreement with SSAB, to become the first original equipment manufacturer of heavy-duty earth scrapers to pilot SSAB Fossil-free™ steel in its earthmoving product line.

Part of the K.A. Group, K-Tec takes the first step toward eliminating carbon emissions by focusing on material selection. As a fossil-free partner to SSAB, K-Tec will have access to pilot deliveries of SSAB Fossil-free™ steel, which has virtually zero carbon dioxide emissions from the steelmaking process. The steel initially will be used in K-Tec’s key products serving the construction and mining industries.

K.A. Group’s President and CEO, Dan Pashniak says, “We are thrilled to have our K-Tec earthmoving equipment brand as the first scraper solution to incorporate SSAB Fossil-free™ steel, continuing our commitment to innovation. It is also an honor for our organization to be the first Canadian manufacturing partner to collaborate with SSAB in this crucial initiative to lead our industry. We are excited to partner with SSAB as they strive to provide environmental steel solutions to advance towards a sustainable future.”

This collaborative initiative is K-Tec’s next step in reducing emissions and improving sustainability for its customers. The company already designs, manufactures and delivers strong, lightweight earthmoving equipment built with SSAB’s Hardox® wear steel and Strenx® performance steel brands.

The massive advantage of K-Tec scrapers is using lightweight, strong steel, so that contractors can haul more material, instead of heavy iron. Additionally, K-Tec’s high-capacity scrapers allow for greater production requiring less cycles per day to shrink the earthmoving carbon footprint compared to traditional methods of earthmoving.

“This partnership demonstrates the commitment from both companies toward reducing carbon emissions,” says Johnny Sjöström, Head of Special Steels at SSAB. “Our transformation to change the way steel is made is well underway, and we are proud to already have reached this far in our journey towards a fossil-free future.”

As a market leader in premium steels, SSAB plans to revolutionize the entire steelmaking process by producing steel with virtually zero carbon dioxide emissions. The pilot deliveries of SSAB Fossil-free™ steel are made using the unique HYBRIT-technology, which was jointly developed by SSAB, iron ore producer LKAB and energy company Vattenfall. It replaces the coking coal traditionally used for iron ore-based steelmaking with fossil-free electricity and green hydrogen. The by-product is water instead of carbon dioxide emissions.

About K-Tec

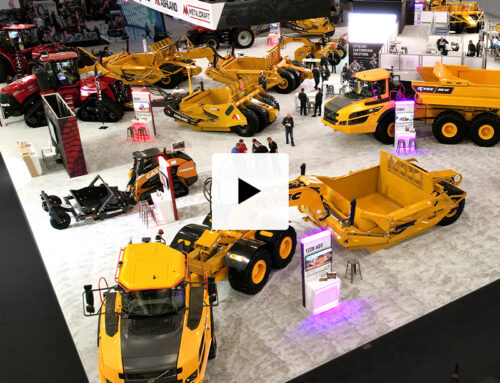

K-Tec Earthmovers is a manufacturer of pull-pan ejector earthmoving scrapers and accessories for the construction & mining industries. K-Tec’s high-capacity, minimal maintenance, lightweight, & durable scrapers have proven to work in topsoil, clay, sand, gypsum rock, and coal applications. K-Tec’s scrapers efficiently complete 3 functions of earthmoving by picking up material in the cut zone, transporting the load down a haul road, and smoothly ejecting the material in the desired fill area on a jobsite. K-Tec scraper capacity ranges from 28-63 cubic yards, pulled by Tractors or Articulated Dump Trucks (ADT’s), resulting in the largest scrapers in the marketplace, allowing for greater production requiring less cycles per day to shrink the earthmoving carbon footprint compared to traditional methods of earthmoving. K-Tec scrapers have 2 daily grease points, to spend time more productively. K-Tec has an industry leading 3-year structural warranty and ISO 9001:2015 certification to stand behind the quality and workmanship of scrapers. For more information, visit www.ktec.com.

About SSAB

SSAB is a Nordic and US-based steel company that builds a stronger, lighter and more sustainable world through value added steel products and services. Working with our partners, SSAB has developed SSAB Fossil-freeTM steel and plans to reinvent the value chain from the mine to the end customer, largely eliminating carbon dioxide emissions from our own operations. SSAB Zero™, a largely carbon emission-free steel based on recycled steel, further strengthens SSAB’s leadership position and our comprehensive, sustainable offering independent of the raw material. SSAB has employees in over 50 countries and production facilities in Sweden, Finland and the US. SSAB is listed on Nasdaq Stockholm and has a secondary listing on Nasdaq Helsinki. Join us on our journey! www.ssab.com, Facebook, Instagram, LinkedIn, X and YouTube.

For further information, please contact:

At SSAB: Anna Molin, Corporate Communications, anna.molin@ssab.com, +146 76 110 46 76

At K-Tec: Shane Kroeker, Director of Strategic Initiatives, Shane.Kroeker@kagroup.com, +1 204 746 6435 ext 258